Formply Australia How to Source Durable Panels for Heavy Concrete Loads

What Is Formply and Why Is It Essential for Heavy Concrete Loads?

Formply is engineered plywood specifically manufactured for concrete formwork applications, designed to withstand the extreme pressures and moisture exposure that come with pouring heavy concrete loads. Unlike standard plywood, this specialised material combines high-quality timber veneers with advanced bonding technologies to create panels that maintain structural integrity under demanding construction conditions.

The material serves as temporary moulds or shuttering that holds wet concrete in place until it cures and gains sufficient strength. When dealing with heavy concrete loads—such as those found in multi-storey buildings, bridges, or industrial structures—the formwork must support substantial weight without deflecting, warping, or failing. Formply Australia panels excel in these scenarios because they’re engineered to handle these pressures whilst delivering consistent results across multiple uses.

Core Features That Define Formply’s Performance

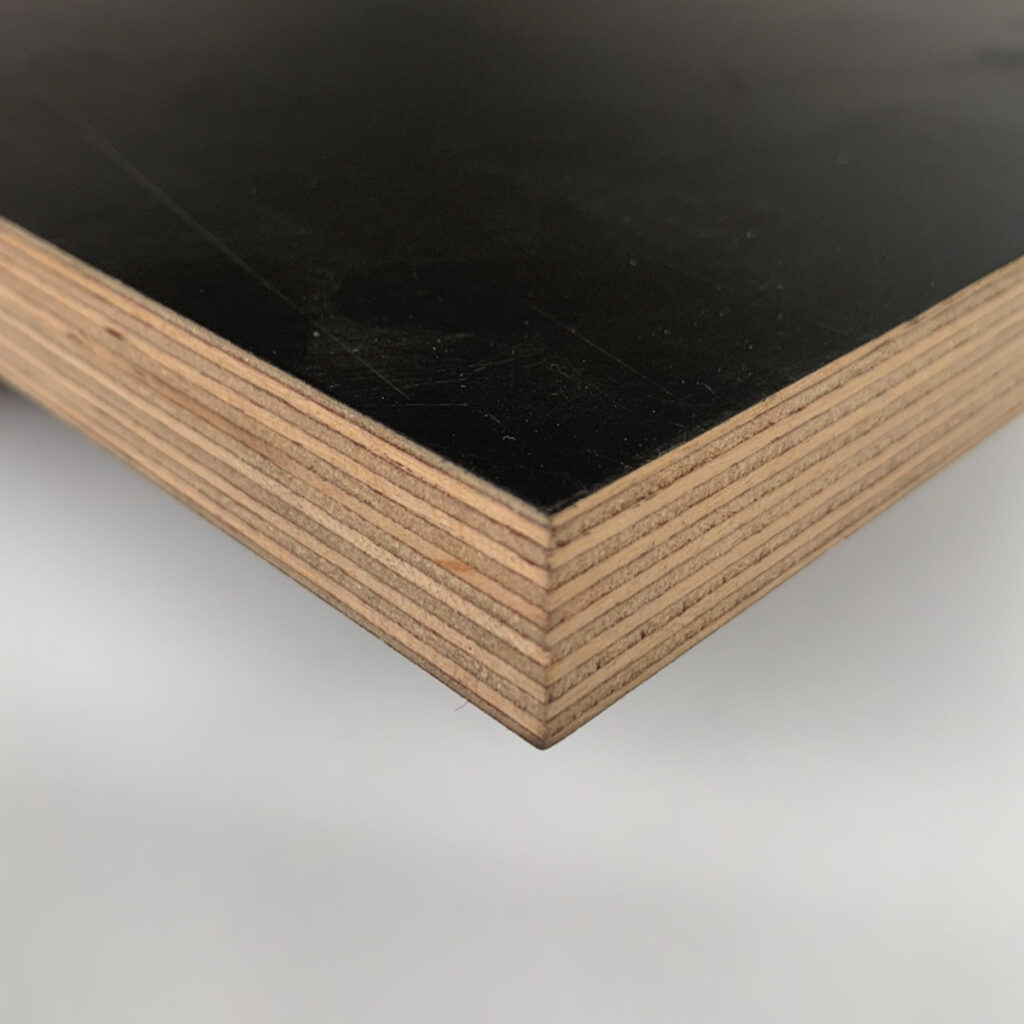

The load-bearing capacity of formply panels stems from their multi-layered construction. Manufacturers laminate high-quality timber veneers using A-type marine bonding techniques, creating a composite material that distributes weight evenly across the panel surface. This construction method prevents weak points that could lead to catastrophic failure during concrete pours.

Durability stands as another defining characteristic. Formply panels resist the harsh conditions typical of construction sites:

- Moisture exposure from wet concrete and weather

- Chemical contact from concrete additives and curing compounds

- Physical stress from repeated installation and removal

- Temperature fluctuations across different seasons

The Critical Role of Phenolic Resin Technology

Phenolic resin glue forms the backbone of formply’s exceptional performance. This synthetic polymer creates an incredibly strong bond between timber veneers that remains stable even when saturated with water. The resin penetrates the wood fibres during manufacturing, creating a moisture barrier that prevents delamination—a common failure mode in inferior plywood products.

Marine bonding techniques take this protection further. Borrowed from boat-building industries where materials face constant water exposure, A-type marine bonding ensures that formply panels maintain their structural properties even when subjected to prolonged moisture contact. This bonding method uses waterproof adhesives that meet stringent durability standards, allowing panels to survive

Which Australian Standards Ensure the Quality of Formply Panels?

AS 6669 and AS/NZS 2269 are the main regulations that govern the quality of formply in Australia. AS 6669 specifically focuses on plywood used for structural purposes, setting minimum standards for strength, stiffness, and dimensional stability. On the other hand, AS/NZS 2269 covers plywood and blockboard used for general applications, including manufacturing processes, bonding quality, and veneer grades.

These standards work together to ensure that formply panels meet strict performance criteria before they are delivered to construction sites. Compliance testing verifies that the panels can withstand the intense pressures exerted by wet concrete without compromising their structural integrity. The standards require manufacturers to achieve specific load-bearing capacities, deflection limits, and stress tolerances through controlled production methods.

Guaranteeing Moisture Resistance and Bond Durability

The moisture resistance requirements outlined in these standards protect the panels from damage when exposed to wet concrete and outdoor conditions. Testing protocols measure how much water the panels absorb, how much they swell in thickness, and how much their dimensions change after being exposed to moisture for a long time. The panels must show minimal water penetration and retain their shape even when saturated.

Bond durability testing ensures that the phenolic resin adhesive used in the panels maintains its strength even after multiple concrete pours. The standards require the panels to pass boil tests, where samples undergo repeated cycles of boiling and drying to simulate years of being on-site. Only panels that maintain their laminate integrity without any delamination will receive certification.

Surface Finish Specifications

The standards define different classifications for surface quality that determine how smooth or imperfect the finished concrete will be. Class 1 and Class 2 surface ratings specify the maximum allowable defects, grain patterns, and smoothness levels. These classifications help contractors choose the right panels based on whether they want the concrete surface to be visible or hidden.

Veneer quality grades outlined in AS/NZS 2269 establish acceptable limits for natural characteristics like knots, splits, and patches. Higher-grade veneers produce smoother concrete surfaces with fewer imperfections, reducing the need for post-pour finishing work.

Why Compliance Matters When Sourcing

Buying non-compliant panels introduces significant risks to project safety and quality. Panels without proper certification may fail under load, causing concrete blowouts, structural collapse, or worker injuries. The financial

What Are the Recommended Grades of Formply for Heavy Concrete Loads?

F17 formply is the industry standard for heavy concrete applications. It has a thickness of 17mm and a strong construction that can support heavy loads. This grade uses eucalyptus plywood or walnut veneers bonded with phenolic resin, making it able to withstand large amounts of wet concrete pressure without bending. The phenolic film coating on both sides provides excellent protection against moisture and chemicals during multiple concrete pours.

F14 grade is an alternative option for projects with moderate load requirements. It has a thickness of 14mm, which reduces material costs while still maintaining good structural performance. F14 is suitable for lighter formwork applications like residential slabs or low-height walls, but it is not as durable as F17. Contractors working on multi-storey buildings, bridge decks, or industrial structures usually choose F17 because of its superior strength.

The benefits of F17 go beyond just being strong:

- Dimensional stability prevents warping or swelling when exposed to wet concrete, keeping the formwork dimensions accurate throughout the pour

- Class 2 surface finish achieves smooth concrete faces on the first pour, eliminating expensive grinding or finishing work

- Chemical durability resists alkaline concrete compounds and release agents, preserving panel integrity across 15+ reuse cycles

The eucalyptus plywood core in F17 panels naturally resists splitting and delamination under stress. This type of wood has a good strength-to-weight ratio, making it easy to handle the panels on-site while still providing the structural performance needed for heavy concrete loads. The phenolic overlay seals the wood grain, creating a non-porous surface that prevents concrete from sticking and makes it easier to clean the panels between pours.

It’s noteworthy that the phenolic resin used in F17 formply not only adds to its strength but also enhances its resistance to various environmental factors, making it an ideal choice for heavy-duty concrete applications.

How Do Phenolic Resin Overlays Enhance Durability?

Phenolic resin overlays create an impermeable barrier that shields formply panels from moisture penetration and chemical attack during concrete pours. This protective coating bonds directly to the plywood substrate, preventing water absorption that would otherwise cause swelling, delamination, or structural failure.

The phenolic resin overlay transforms standard plywood into a resilient formwork material capable of withstanding repeated exposure to wet concrete. Panels treated with this coating maintain their dimensional stability even when subjected to harsh site conditions, including rain, humidity, and alkaline concrete mixtures. The chemical resistance prevents deterioration from cement compounds, extending the functional life of each panel significantly.

High-Density Overlay (HDO) and Medium-Density Overlay (MDO) represent the two primary phenolic coating options for formply panels. HDO provides superior moisture resistance and durability, making it ideal for heavy concrete loads requiring 15+ pours per panel. The dense surface creates an ultra-smooth finish that produces consistent Class 2 concrete surfaces. MDO offers a cost-effective alternative for projects with moderate reuse requirements, typically delivering 8-12 pours before replacement becomes necessary.

The reuse potential directly impacts project economics. A single F17 panel with HDO coating can replace multiple untreated plywood sheets, reducing material costs and waste. Proper maintenance between pours—including cleaning and edge sealing—maximises this lifespan advantage, making phenolic-coated formply the preferred choice for contractors managing large-scale concrete projects across Australia.

Where Can They Source Durable Formply Panels Across Australia?

Reliable suppliers in Australia stock compliant F14 and F17 formply grades across major metropolitan areas. Builders and contractors should prioritise vendors who maintain consistent inventory levels and can provide certification documentation proving adherence to AS 6669 and AS/NZS 2269 standards.

Stock availability in Sydney, Melbourne, Brisbane, Perth, and Adelaide directly impacts project timelines, particularly for large-scale commercial developments requiring immediate panel delivery. Established timber and building material distributors typically maintain warehouses in these cities, offering same-day or next-day dispatch options. Regional suppliers may require longer lead times, making metropolitan vendors the preferred choice for time-sensitive concrete pours.

Verification of phenolic overlay specifications—whether HDO or MDO—should occur before purchase, as these determine panel reusability and surface quality. Reputable suppliers provide technical data sheets detailing thickness tolerances, moisture content ratings, and expected pour cycles per panel.

How Should They Maintain Formply Panels to Maximise Lifespan?

Proper panel maintenance begins with correct storage practices. Panels must rest on level ground with adequate support underneath to prevent warping or bowing, particularly when stacking multiple sheets. Uneven surfaces create stress points that compromise structural integrity over time.

Edge sealing provides critical protection against moisture ingress. Exposed edges allow water penetration between veneer layers, causing delamination and reducing reuse potential. Apply waterproof sealant to all cut edges immediately after trimming panels to size.

Additional storage tips include:

- Position panels vertically or with slight incline to promote drainage

- Cover stored panels with waterproof tarpaulin whilst maintaining ventilation

- Clean concrete residue promptly after each pour using appropriate solvents

- Apply release agents before concrete placement to prevent surface bonding

- Inspect regularly for cracks, chips, or delamination requiring immediate repair

What Applications Benefit Most from Using Durable Formply Panels?

Formply panels excel across diverse construction applications where strength and dimensional stability matter most. These engineered plywood sheets handle heavy concrete loads in walls, columns, and beams whilst maintaining structural integrity through multiple pours.

The versatility extends beyond traditional formwork:

- Infrastructure projects: bridges, roads, and highways requiring consistent surface quality

- Architectural concrete: achieving Class 2 finishes for exposed structural elements

- Commercial construction: high-rise buildings with repetitive floor slabs

- Civil engineering: retaining walls and foundations under extreme pressure

When sourcing Formply Australia How to Source Durable Panels for Heavy Concrete Loads, contractors benefit from panels that adapt to both vertical and horizontal applications. The phenolic resin coating performs equally well whether forming intricate column shapes or expansive floor systems, making it the preferred choice for projects demanding reliability and reusability.

See Also: Top 5 Mistakes to Avoid When Installing Reobars on Site.

FAQs on Formply for Heavy Concrete Loads

Formply is a high-strength, engineered plywood designed specifically for concrete formwork applications. It’s made from multiple layers of high-quality timber veneers bonded with phenolic resin glue, providing exceptional durability, load-bearing capacity, and resistance to moisture and chemicals during concrete pouring.

Formply panels are engineered to withstand extreme weight, vibration, and pressure from wet concrete. The phenolic resin bonding and marine-grade construction prevent warping, delamination, or structural failure, making it ideal for multi-storey buildings, bridges, and industrial concrete structures.

Unlike standard plywood, Formply is designed for repeated use in wet and demanding environments. It features A-type marine bonding, phenolic film overlays, and dimensional stability, ensuring it doesn’t absorb water or lose strength under heavy concrete loads.

Two key standards ensure the quality and safety of Formply in Australia:

AS 6669: Specifies structural plywood requirements, including strength and stiffness.

AS/NZS 2269: Regulates general plywood manufacturing, bonding quality, and veneer grading.

Compliance with these standards guarantees reliable performance under heavy concrete pressure.

F14 Formply is suitable for moderate concrete loads, such as residential slabs or low-height walls.

F17 Formply offers superior strength and moisture resistance, ideal for multi-storey buildings, bridge decks, and large-scale industrial projects.

F17 also supports more reuse cycles and produces smoother Class 2 concrete finishes.

Phenolic resin forms a moisture-proof and chemical-resistant barrier that seals the timber veneers. This prevents swelling, delamination, and deterioration from concrete’s alkaline compounds. It also enables Formply panels to endure 15+ reuse cycles with proper maintenance.